.For the prices or for order, please contact your sales representative Kemex.

Safety manual and Operation

DTF-76 MANUAL TENSIONER

GENERAL SAFETY CONSIDERATIONS:

Kemex Strapping Systems 1850, Transcanadienne, ++++.Dorval (Québec) + + . Tél: 514-685-1119 +++++.800-755-3639 ++. +..Fax: 514-685-2228

1. EYE INJURY HAZARD.

Failure to wear safety glasses with side shields can

result in severe eye injury or blindness. Always wear

safety glasses with side shields which conform to ANSI

Standard Z87.1.

2. STRAP BREAKAGE HAZARD.

Improper operation of the tool or sharp corners on the

load can result in strap breakage during tensioning,

which could result in the following:

. A sudden loss of balance causing you to fall.

. Both tool and strap flying violently towards

your face.

Failure to place the strap properly around the load or on

an unstable or shifted load could result in a sudden loss

of strap tension during tensioning. This could result in

a sudden loss of balance causing you to fall.

Read the tools operating instructions. If the load

corners are sharp use edge protectors. Place the strap

correctly around a properly positioned load.

Positioning yourself in-line with the strap, during

tensioning and sealing, can result in severe personal

injury from flying strap or tool. When tensioning or

sealing, position yourself to one side of the strap and

keep all bystanders away.

3. FALL HAZARD.

Maintaining improper footing and/or balance when

operating the tool can cause you to fall. Do not use the

tool when you are in an awkward position.

4. CUT HAZARD.

Handling strap or sharp parts could result in cut hands

or fingers. Wear protective gloves.

5. TRAINING.

This tool must not be used by persons not properly

trained in their use. Be certain that you receive proper

training from your employer. If you have any questions

contact your Kemex Representative.

6. TOOL CARE.

Take good care of the tool. Inspect and clean it daily,

lubricate it weekly and adjust when necessary. Replace

any worn or broken parts.

7. WORK AREA.

Keep work areas uncluttered and well lighted.

STRAP SPECIFICATIONS

Width: 5/8" to 3/4" Steel

Gauge: Up to .035" Thick

OPERATING INSTRUCTIONS:

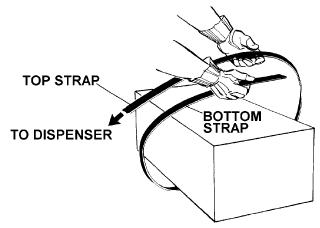

1. Drape strapping around the container as illustrated.

Take up slack, keeping straps squarely in line.

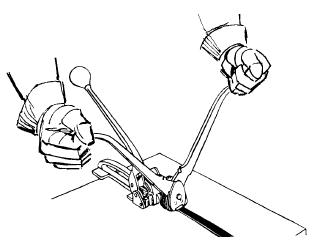

2. While standing to one side of the strap line, hold the

hand tensioned strap in position with your left hand,

grasp the tool in your right hand and squeeze the

handle to the base, thus, lifting the feedwheel. Position

the rear foot over the strap and then slide the front foot

under the overlapping ends approximately 1" ahead of

the lower strap end.

3. Release grip on tool

to engage strapping,

being sure strap is in

alignment with tool.

Tension is obtained

through continuous up and

down motion with the

handle.

WARNING:

On downward strokes

do not allow the handle to press against

the base as this will raise the feedwheel

and release the tensioned strap.

4. Snap seal on both layers of strap

directly in front of the tool.

5. Hold the

sealing tool

at a right

angle to the

strap, resting

it squarely

over the seal.

Seal the

tensioned strap

by bringing the

sealer handles

together as far as they will

go.

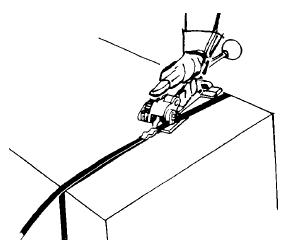

6. Return the tensioning handle

to rest on the tool, depressing

the handle pawl with your thumb.

Squeeze the handle to the base and

remove the tool from the strap by

swinging the rear foot out as

illustrated.

7. Carefully bend the excess strap sharply back on the

seal. If the excess strap is

loose (not connected to a

dispenser) hold down on the

loose end of strap to prevent

personal injury.

Additional bends will

result in a clean

strap break off.

OPERATING INSTRUCTIONS:

5.

6.